INOSIM Statistical Analysis

Predicting the Unpredictable

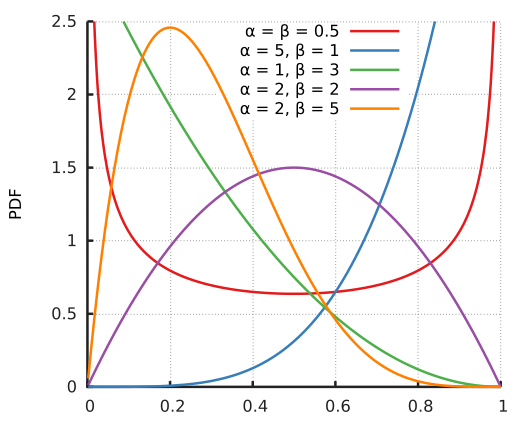

Generate expressive statistics for uncertain influences in your process such as fluctuating market demands, failures, or even random variations in production recipes. Applying statistical distribution functions to your simulation model enables the user to recognize upcoming problems and implement a plan to minimize, or possibly eliminate, the problems altogether.

Wide Scope of Applications

In production, process variability is inevitable. Even the most robust processes experience at least some degree of variability.

These deviations, whether big or small, can aggregate over time and result in production delays or worse, product losses. That is why it is so important to design your process in such a way to account for these variations by using statistical analysis.

Some of the more common use cases are:

- Unit failures

- Deviations due to the aging of machines

- Variations in processing parameters such as durations, yields, resources, etc.

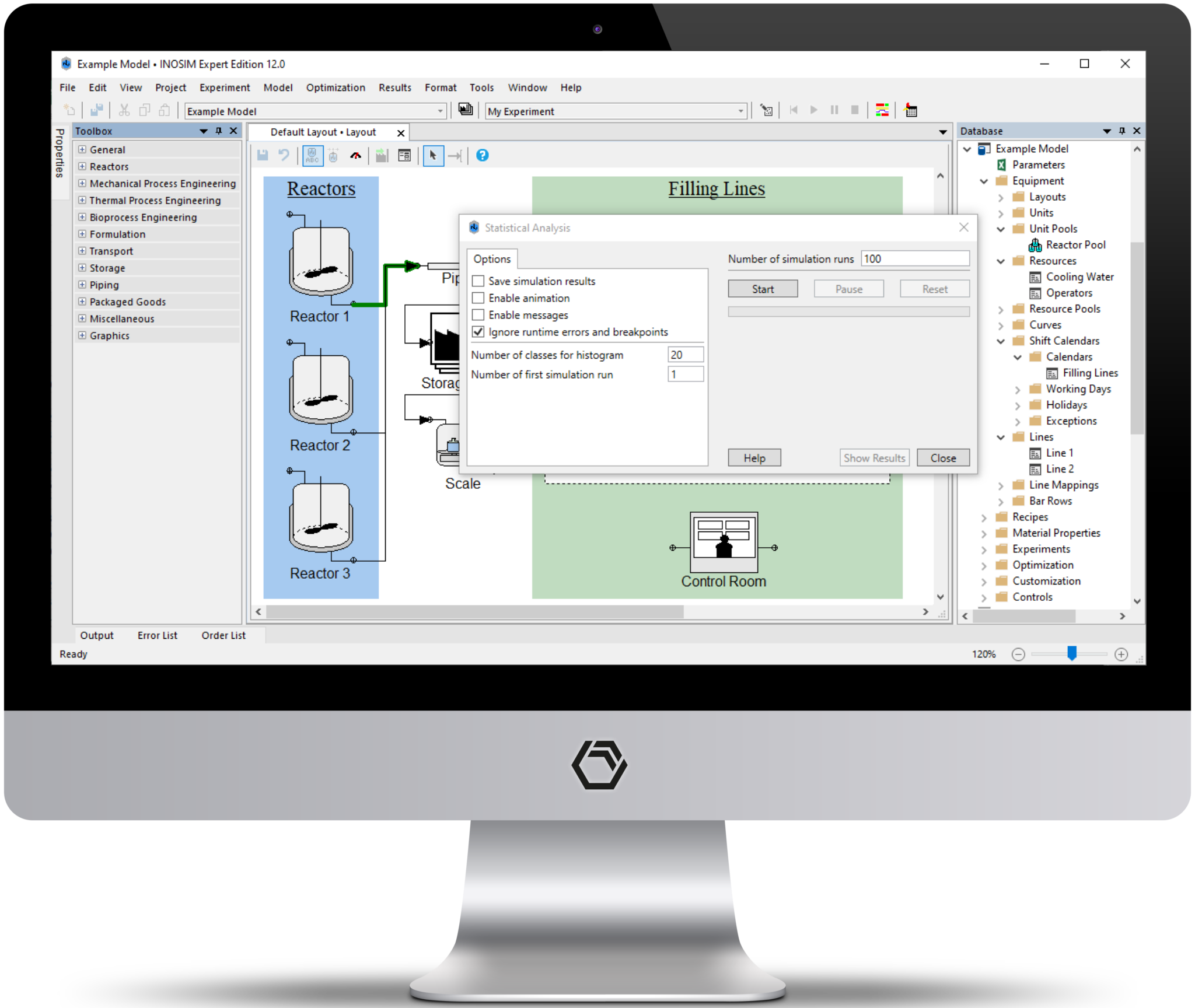

Simple Analysis

As an integrated plug-in, INOSIM’s Statistical Analysis is embedded into your INOSIM simulation application, enabling you to apply statistical fluctuations to your already existing simulation model.

Features to support your analyses:

- Modify the number of simulations runs

- Apply default and/or user-defined criteria

- Interrupt the statistical analysis at any time to check out random samples

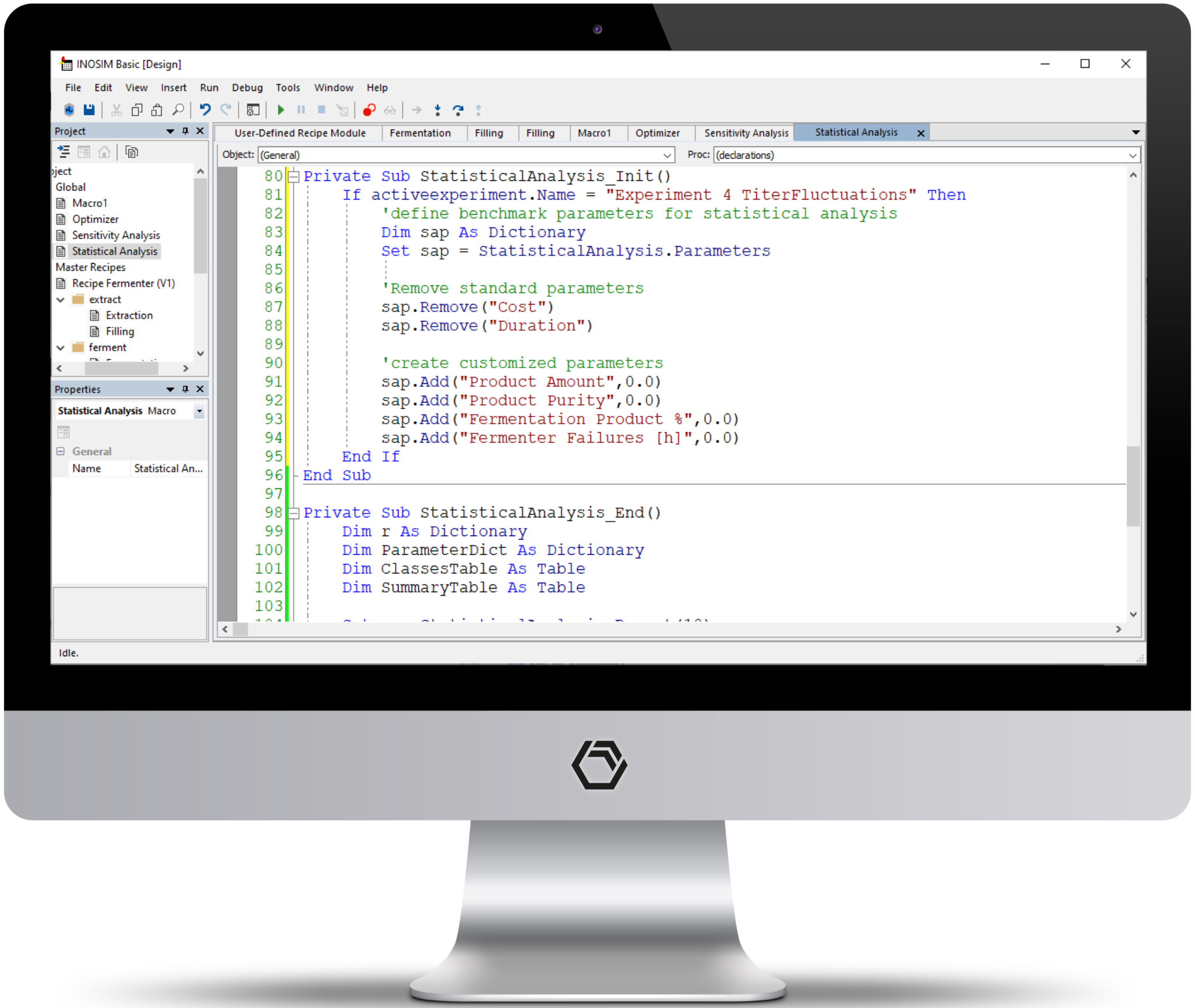

Easy Evaluation

The default parameters for a statistical analysis are:

- Duration of the simulation run

- Total cost of the simulation run

Of course, you may also define your own parameters in addition to or in place of the default parameters. Some examples:

- Batch cycle times

- Production delays

- Failure or maintenance frequencies

- Unit utilization

- Filling levels of storage tanks

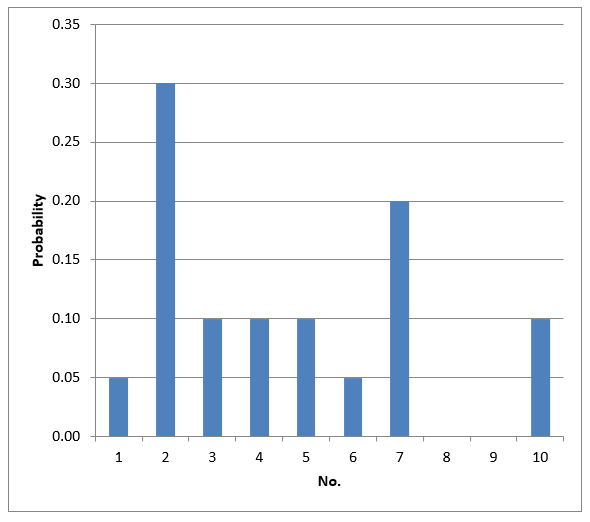

Reproducible Results

When you are simulating random processes, reproducible results are essential to ensure the quality of your statistical analyses.

That is why INOSIM’s Statistical Analysis provides you with identical start conditions and streams of reproducible random numbers for the repetition of your crucial simulation runs.