INOSIM Optimizer

Optimizing Process and Production

Calculate optimum production and process parameters by applying a genetic algorithm to your existing simulation model. With justifiable effort, you can quickly optimize production costs, tank dimensions, sequences of units, or any other parameter that you define.

Optimizer Features

- Target function: Define your optimization target (e.g., minimize production time or costs)

- Parameter selection: Define the parameters to be optimized (e.g., order sequence, production recipes, etc.)

- Optimization settings: Set the parameter properties of the optimization algorithm (e.g., number of generations or individuals per generation)

- Stochastic optimization: Enable random events to influence your model (e.g., fluctuating raw material prices)

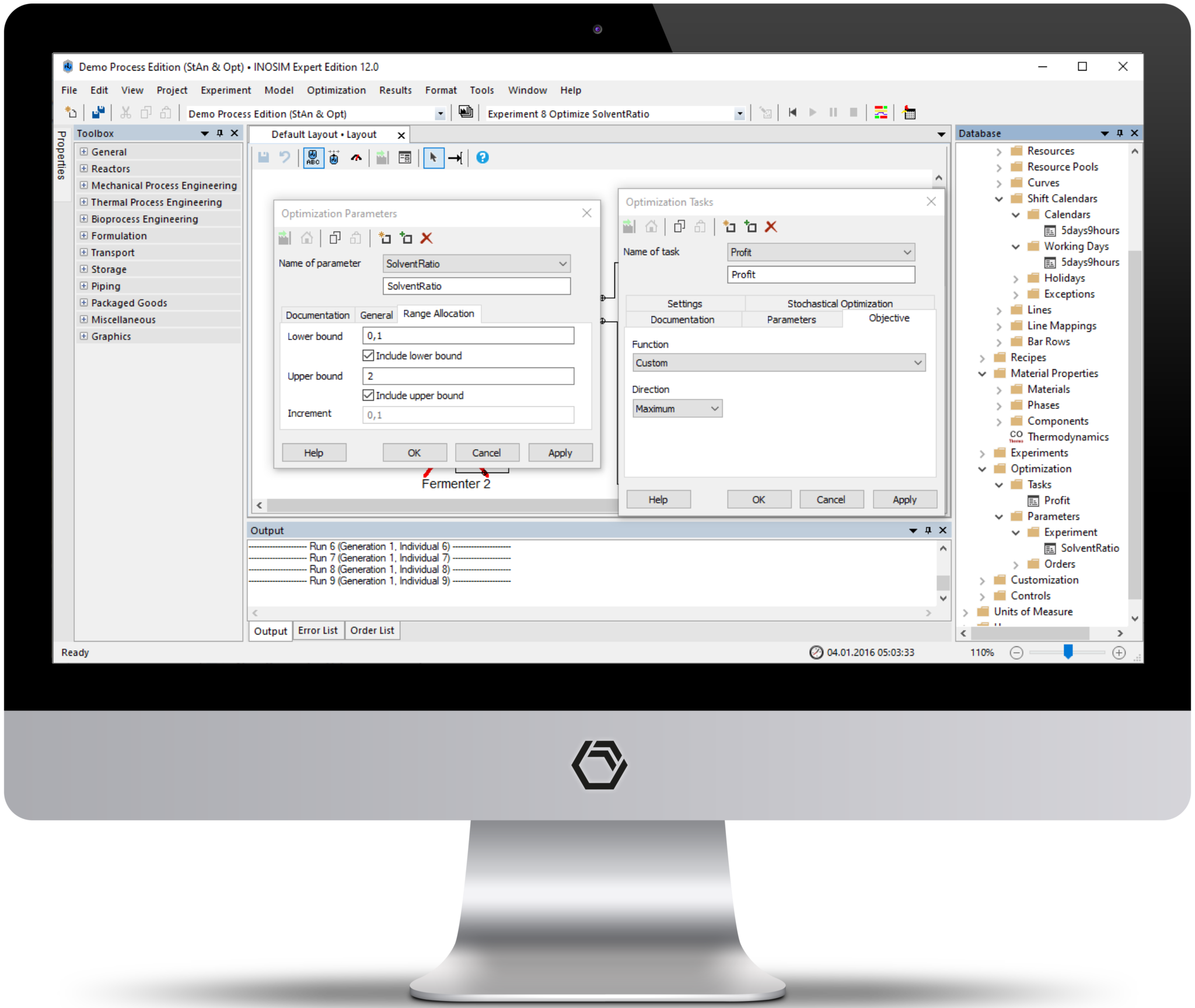

Optimization Parameters

The default parameter options are:

- Order Sequence

- Production Recipes

Nevertheless, you may optimize any parameter within your simulation model from simple numeric values up to complete plant structure, depending on your exact needs.

The user-friendly parameter management function provides you with the following options:

- Select parameters from the INOSIM database

- Assign parameters to a specific experiment or order

- Define the parameter as discrete or continuous

- Define upper and lower bounds for each parameter (An incremental definition is also possible)

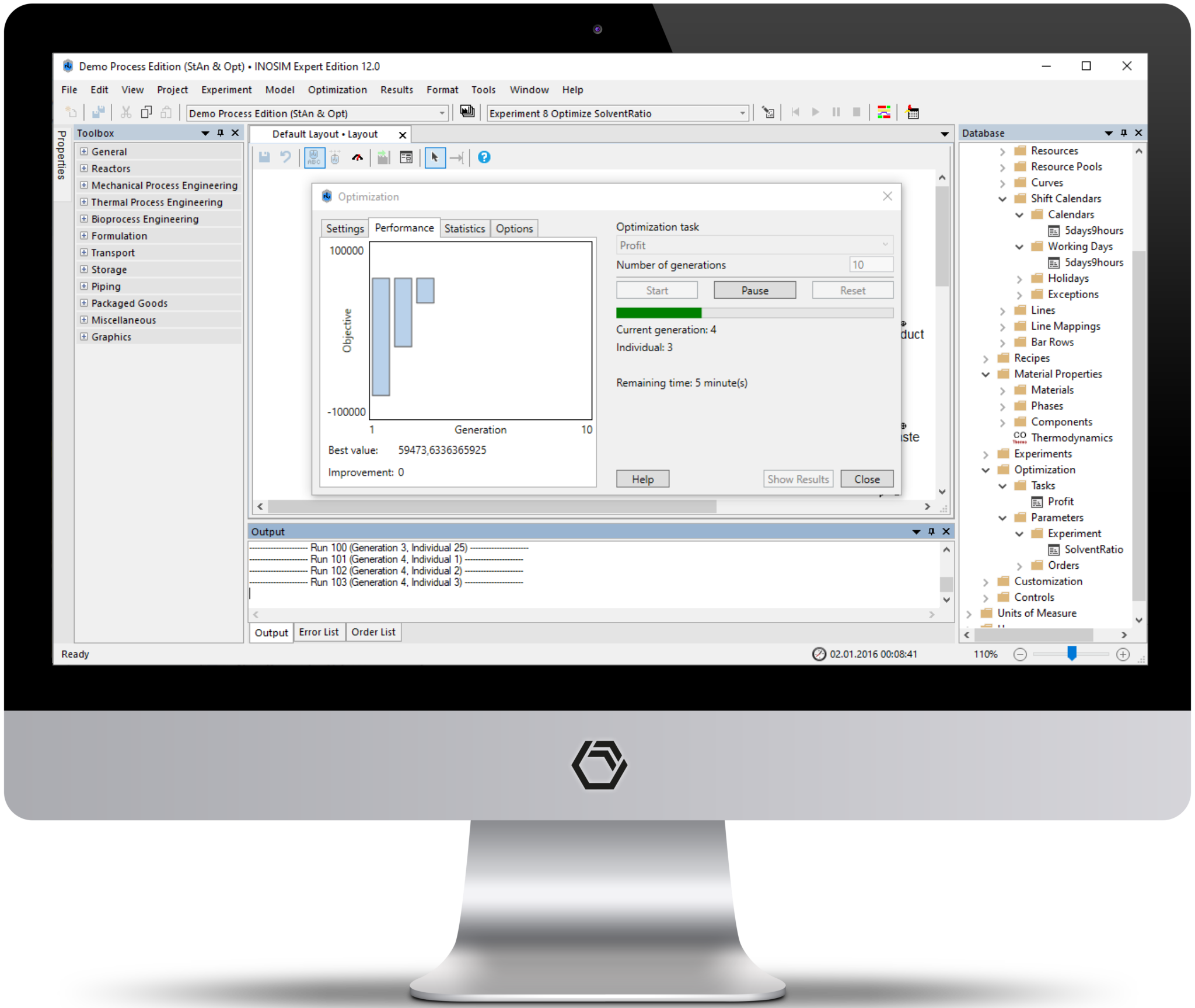

Find the Best Solution

It is the optimizer’s job to detect the best possible set of results based on your specifications.

A bar chart indicates the progression of your model’s improvements by displaying the range between the best and worst solutions currently found.

In the case of stochastic optimization, INOSIM’s Optimizer integrates varying influences into your simulation model, then organizes your results into defined confidence intervals for comprehensive analysis.

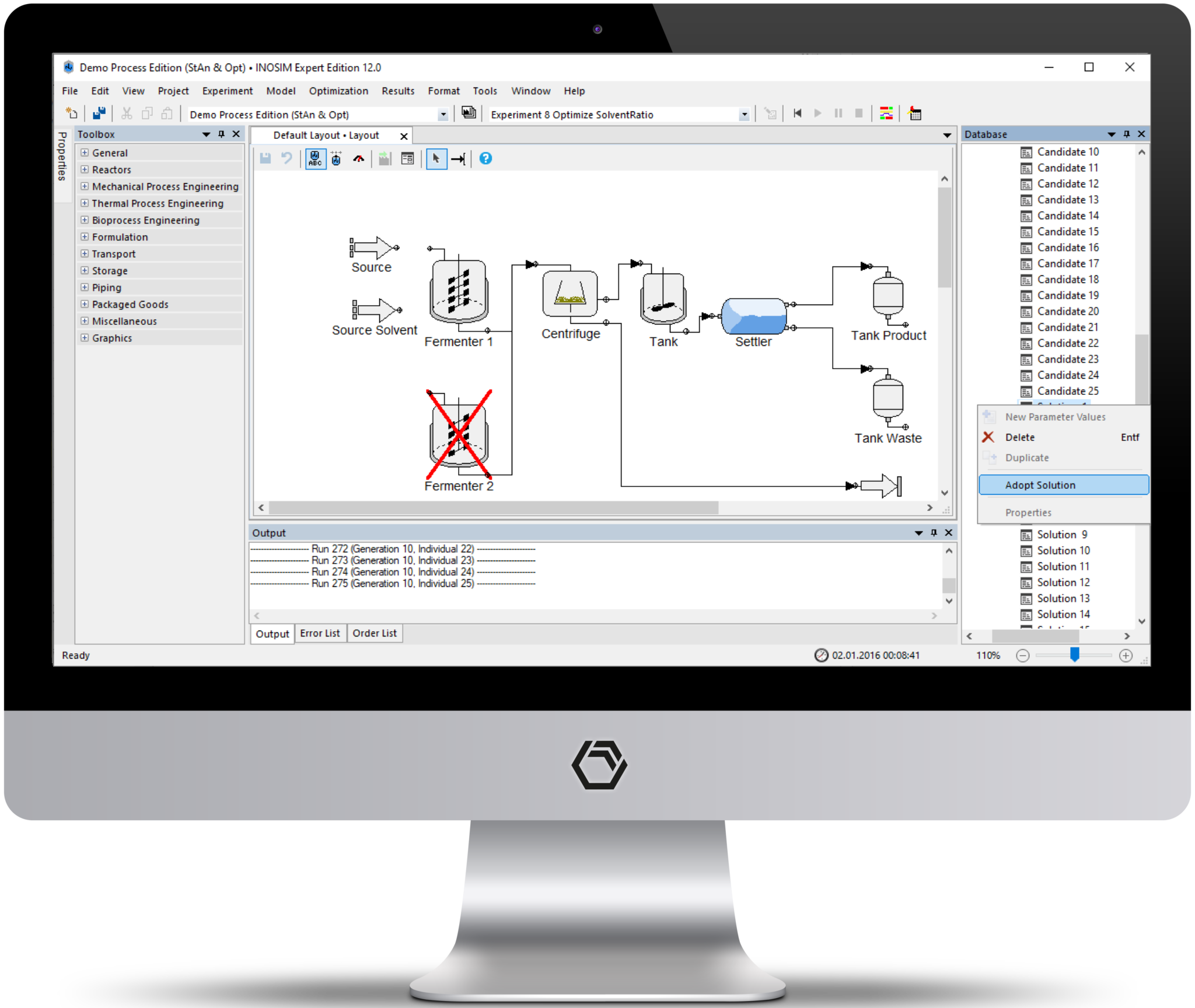

Apply the Results

After a defined number of simulation runs, the INOSIM Optimizer calculates the optimal parameters to best achieve your defined target.

These results are then made readily available in your INOSIM database so that you may easily implement them into your model. Then, you may validate your results afterward by further simulation.